How Much Faster Can I Freeze Dry by Adding Heat?

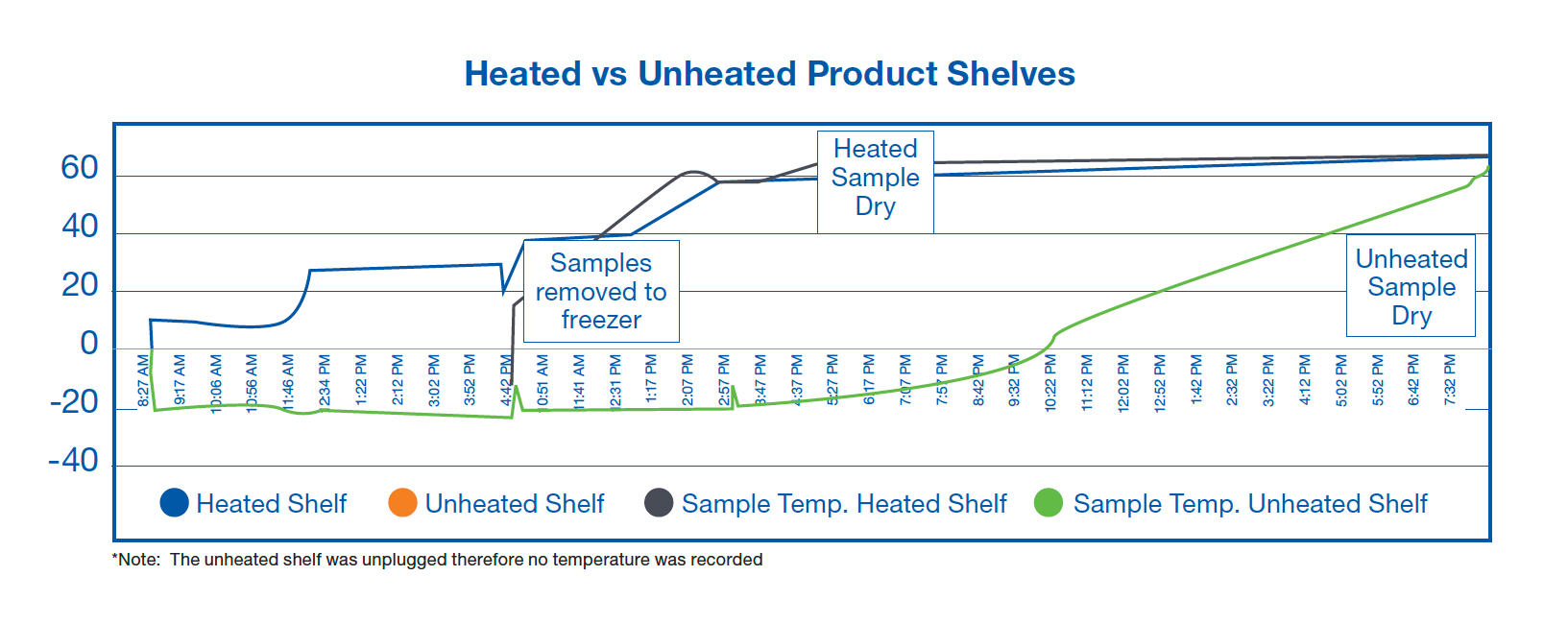

The process of freeze drying, or lyophilization includes pre-freezing, primary drying and secondary drying of samples. Sublimation is a time-consuming process, but the process can be optimized with heat input, speeding up the lyophilization process. The biggest question is how much heat can be added before it has a detrimental effect on the lyophilization process. In our experiment we prove that the sublimation rate can be improved by 53% with heat input.

Equipment. Labconco 4.5L -105°C (720401000) Freeze Dryer, Small Tray Dryer (780701000) and Hybrid Vacuum Pump (7584000).

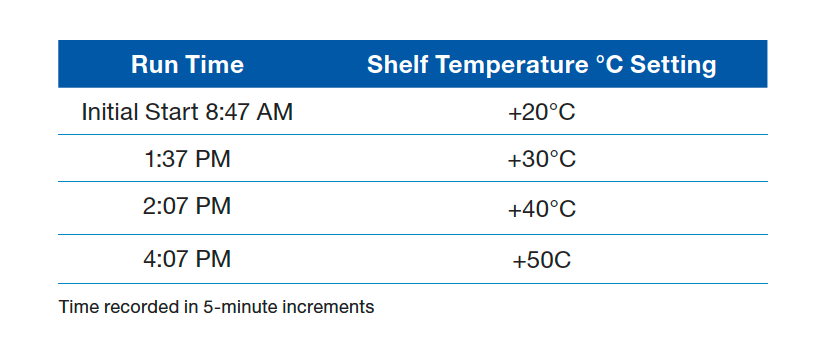

Method. Two trays with 1000mls each of RO water were pre-frozen overnight at -25°C. One tray was placed on a shelf with no heat input. The other placed on a shelf with a shelf temperature programmed at +20°C. The vacuum set point was 0.2mbar throughout the run.

The freeze dryer was started in manual model, the samples were loaded onto their respective shelf and the vacuum pump was started. The heated shelf samples were watched for sample melt back at the +20°C start point. When no melt back was observed, the shelf was increased incrementally by 10 degrees at a time over a period of 8 hours up to +50°C.

Conclusion. By adding controlled heat to the sample, the heated sample was dry in 13 hours and 20 minutes, the unheated sample was dry in 27 hours and 41 minutes. A 53% improvement in sublimation rate was achieved when using controlled heat.

| chevron_left | Lyophilizing Small Samples | Articles | The Solvent Cabinet—a Laboratory Super Hero | chevron_right |