These stainless steel or fiberglass-lined glove boxes have the capability to function as either a filtered box or a controlled atmosphere box.

Protector Combination Glove Boxes

Protector Combination Glove Boxes provide inlet and outlet HEPA or ULPA filtration and a leak-tight physical barrier to protect the operator from exposure to potentially hazardous materials and perform work with contamination-sensitive materials under vacuum or in an inert environment. Protector Combination Glove Boxes feature two internal valves to convert the glove box from a flow-through filtered box to an inert atmosphere glove box.

Need an ultrapure inert atmosphere? All Protector Combination Glove Boxes are compatible with the new AtmosPure Re-Gen Gas Purifier accessory, which has the capacity to remove up to five liters of oxygen (13,500 ppm) and 660 grams of moisture (18 million ppm) at standard temperature and pressure (STP).

Filters applied

Showing 1 - 1 of 1 Results

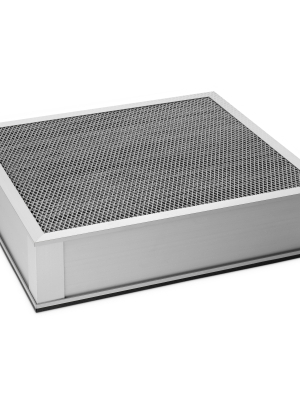

Protector Stainless Steel Combination Glove Box

- Region: U.S. and Canada

- Filter Type: ULPA

- Interior Working Width: 35.5"

- Liner Material: Stainless Steel

- Number of Glove Ports: Two

- Power Cord & Plug: North America, 208-230 Volts

- Primary Application: Atmosphere-sensitive materials, Hazardous materials

- Product Subcategory: Combination Glove Box

Our Product Representatives Are Here To Help

Connecting Gas and Vacuum to a Glove Box

This instructional video shows how to connect gas and vacuum to a Labconco Glove Box with Auto Pressure Controller. Contact Labconco with additional questions not addressed in this video.

Literature & Resources

lock Login or register to download resourcesBrochures

Protector Glove Boxes Catalog

Provides an overview, features and benefits, specifications, ordering information and dimensional data on Protector Filtered Glove Boxes, Protector Controlled Atmosphere Glove Boxes, Protector Combination Glove Boxes and AtmosPure Re-Gen Gas Purifiers. Accessories and Base Stands are also described.

User's Manuals

Protector Controlled Atmosphere Glove Box Manual

For Protector Controlled Atmosphere Glove Boxes manufactured after November 2010

Declarations of Conformity

ETL Authorization Mark for Protector Glove Boxes

This document from Intertek authorizes the use of the ETL mark on Protector Glove Boxes.