Axiom Week: Day 5

FAQs, Myths, Fabrications & Misinformation about the Type C1 Purifier Axiom - Part 5

---

What are the Axiom’s advantages over Type B1 and B2 BSCs?

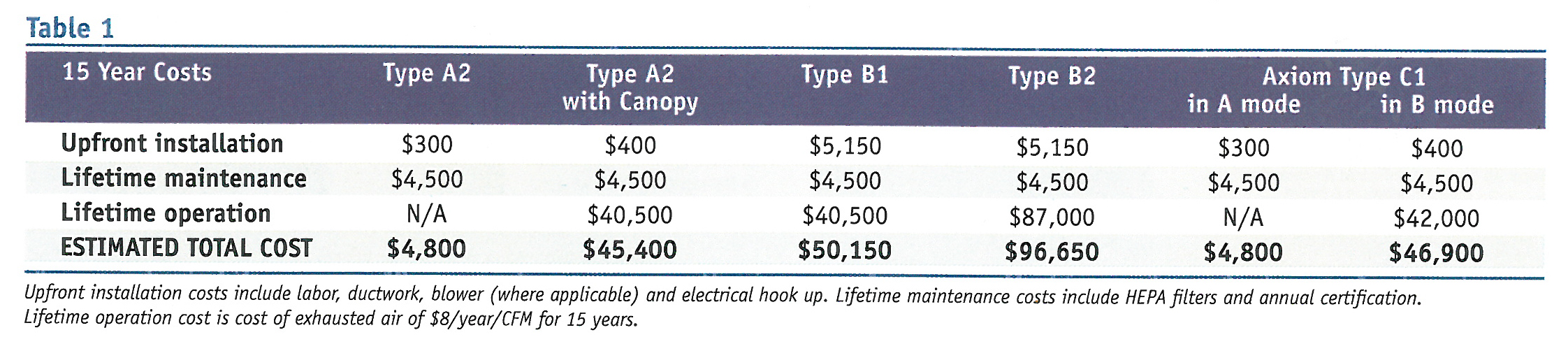

The Axiom outperforms each of the Type B BSCs in regards to safety and flexibility. Though similar in airflow to a B1, the Type C1 does not require special considerations when handling hazardous chemistry, nor does it require a dedicated exhaust system. A B1 BSC cannot operate without exhaust and therefore will always require the infrastructure and cost associated with moving expensive tempered air. The Axiom can be removed from ductwork, eliminating or reducing the cost associated with exhaust air.

A Type B2 BSC experiencing a remote exhaust failure can pressurize the work zone, pushing contaminated air into the laboratory. The C1 BSC is easily adapted and/or manifolded into an existing building exhaust system, and should there be a failure, it protects the laboratory and the operator for an additional 5 minutes. Type B2 BSCs also heavily tax exhaust systems with large volumes that can exceed 1,200 CFM – this can cost over $100,000 per BSC to operate over its life. The C1 reduces this volume by over half, saving over $50,000 per BSC.

An A2 can be ducted to handle odors and non-hazardous chemistry and it is easily adapted to exhaust systems. It can never offer the chemical protection of the Type B or C BSCs because it does not have single-pass airflow.

Type A and Type B BSCs cannot be retrofitted, altered or otherwise made into the other type of cabinet. The Type C1 adopts the strengths of the Type A and B BSCs while addressing their limitations and is cross functional.

Conclusion

This information is provided to educate and inform life science and biosafety laboratories about their new options in selecting Class II BSCs for varying applications and operations. In summary:

- The designation of the Axiom is currently being reviewed by NSF/ANSI Standard 49. It will be designated something other than a Type A or Type B, will be defined as such, and upon completion will be recognized by NIH, CDC, CFIA, and PHAC. The Axiom is NSF Listed for product and personnel protection when installed in both ducted and recirculating modes.

- The airflow in the Axiom, though similar to other existing Class II BSC types, is different and allows for greater flexibility, operational safety, safety during building system failures, and has a lower price/cost burden.

- Like all Class II BSCs, a risk assessment should be performed in order to select the proper Class II BSC; however, the Axiom simplifies this process by being suitable for any microbiological application requiring a Class II BSC.

- The inclusion of a Bag-in/Bag-out (BIBO) option on the Axiom makes it a suitable replacement for any Type B1 or B2 application and installation. The BIBO option is used for chemical (pharmaceutical) powders and radioisotopes that cannot be decontaminated.

- In both Type A and Type B modes, the 3-piece work area with dished Chem-Zone work surface provides increased safety and efficiency by promoting organized work behaviors and ergonomics.

- The Active Protection Protocol engages only in emergency building exhaust system failures and provides safety to the BSC operator while they complete their emergency shut down procedures. This is done without posing a risk of exposure due pressurization of the BSCs interior work zone (as seen in direct hard connected Type B BSCs), or by directly forcing chemically contaminated exhaust air into a laboratory (as seen in the positive pressure relief flaps of a Type A2s canopy/thimble).

Watch this video to see the general airflow pattern of the Axiom.

Thanks for joining us for Axiom Week! Please bookmark these pages for future reference.

This is Day 5 out of 5 for Axiom Week, see our post for: Day 1 | Day 2 | Day 3 | Day 4 |

| chevron_left | How to select the right vacuum pump | Articles | Axiom Week: Day 4 | chevron_right |