Time for a New Type of Biosafety Cabinet? – The Axiom

Labconco Corporation will soon go into full production of a new type of Biosafety Cabinet (BSC) – the Purifier® Axiom™. Because of the design and operational differences, Labconco has submitted an Issue Statement to NSF requesting the creation of a new Type designation – the Type C1.

The Axiom Type C1 BSC is the result of a customer request for a Type B2 BSC with efficiency requirements that were impossible* for any B2 BSC that existed at the time. Realizing the value of what the customer desired, Labconco began development of a Class II BSC that could meet this exhaust requirement, while providing the same safety as a Type B.

Here’s what the new Type C1 does, and how it is achieved:

Airflow Patterns and Features

The overall airflow pattern in the Type C1 is similar to a Type B1, with four important differences:

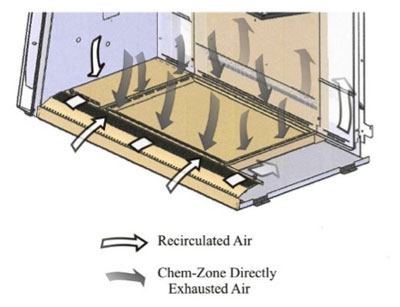

1. In the C1, the directly exhausted portion of downflow air is taken from the center of the work area (The Chem-Zone™).

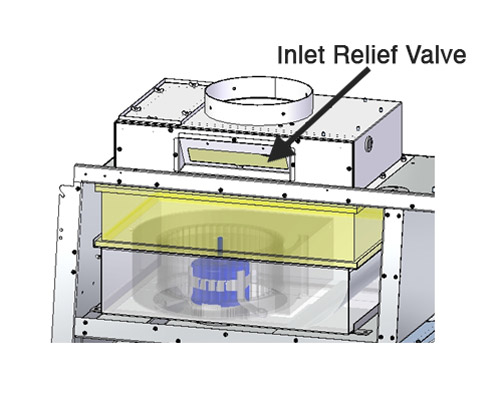

2. An inlet relief valve, unique to the Axiom, stabilizes the inflow as exhaust system airflows fluctuate, and closes during an exhaust system failure, signaling the Axiom to initiate a timed “Active Protection” of the user and their work.

3. A constant volume exhaust blower upstream of the Exhaust HEPA filter maintains constant inflow, and allows the unit’s blowers to continue to operate for a fixed period of time during an exhaust system failure (Active Protection), maintaining safe inflows and downflows while the user secures any hazardous materials in the work area.

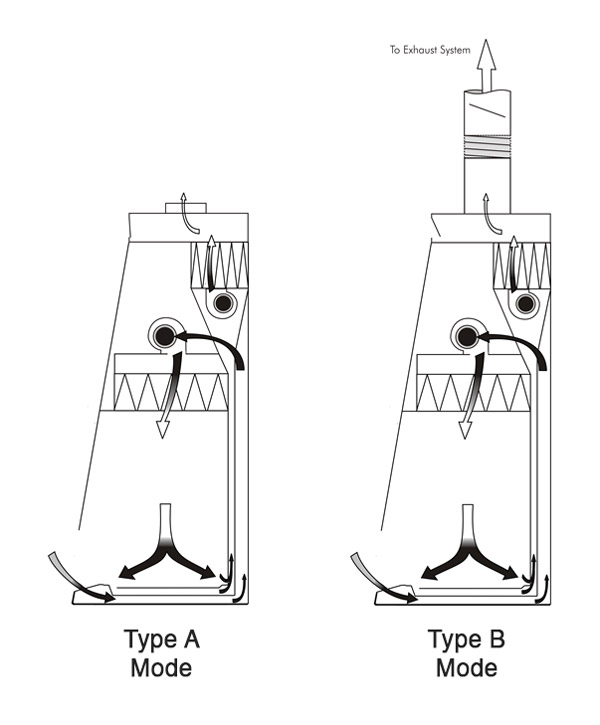

4. The C1 can be configured to direct its HEPA-filtered exhaust back into the laboratory (Type A mode), when chemical hazards are not being used in the cabinet; something no Type B BSC can do.

Chem-ZoneTM Directly Exhausted Work Zone

Unique to the Axiom Type C1 BSC is the Chem-Zone, a directly exhausted work zone. The central portion of the work surface is recessed, and surrounded by grilles on the sides, front and back. Air entering these grilles is drawn to the Exhaust HEPA filter, and when the cabinet is connected to an exhaust system, out of the laboratory. This feature prevents the recirculation of volatile chemicals as seen in Type A cabinets, while exhausting much less air than Type B2 models. This clearly delineated zone of direct exhaust is an advantage over the often unmarked, shifting smoke split of the current Type B1s .

Unique to the Axiom Type C1 BSC is the Chem-Zone, a directly exhausted work zone. The central portion of the work surface is recessed, and surrounded by grilles on the sides, front and back. Air entering these grilles is drawn to the Exhaust HEPA filter, and when the cabinet is connected to an exhaust system, out of the laboratory. This feature prevents the recirculation of volatile chemicals as seen in Type A cabinets, while exhausting much less air than Type B2 models. This clearly delineated zone of direct exhaust is an advantage over the often unmarked, shifting smoke split of the current Type B1s .

Inlet Relief Valve

Also unique to the Axiom is the Inlet Relief Valve, located near the exhaust system connection. The intake valve is angled such that the incoming make-up (room) air must keep the valve open to maintain normal operation; a loss of exhaust volume will allow gravity to close the inlet valve and open the magnetic switch, resulting in an exhaust alarm.

Also unique to the Axiom is the Inlet Relief Valve, located near the exhaust system connection. The intake valve is angled such that the incoming make-up (room) air must keep the valve open to maintain normal operation; a loss of exhaust volume will allow gravity to close the inlet valve and open the magnetic switch, resulting in an exhaust alarm.

Exhaust System

Also exclusive to the Axiom is its flexibility. When properly configured, the HEPA-filtered exhaust can be recirculated back into the laboratory, as in the current Type A2 BSC.

When connected to an external exhaust system, the operation is similar to a Type B, however, the integral exhaust blower and Inlet Relief Valve changes the operating characteristics of the Axiom.

The CAP™ (Constant Airflow Profile)-programmed exhaust fan motor draws a constant volume of air through the exhaust ductwork and exhaust HEPA filter, and ‘presents’ the air to the exhaust system. This means the inflow volume will remain constant as the exhaust system fluctuates, or as the exhaust HEPA filter loads.

This arrangement lowers the vacuum required to operate the unit to a constant 0.3 inches H2O, far lower than traditional Type B BSCs. This consistent, low vacuum also allows the Axiom to be connected to a properly balanced ganged exhaust system.

Exhaust System Failure

The Axiom is unique in its response to an exhaust alarm. Instead of shutting off the BSC’s blowers, the Axiom starts “Active Protection” – a certifier-programmed interval of up to 5 minutes. During this interval, the Axiom’s exhaust blower speeds up to compensate for the loss of the remote exhaust fan to provide constant inflow. The supply blower maintains downflow. This offers the user time to secure any hazardous material in the BSC. At the end of the Active Protection cycle, the supply blower shuts off, followed by the exhaust fan 10 seconds later, to ensure containment until the unit shuts off completely.

Certification

HEPA filter leak testing is similar to the Type A; both the supply and exhaust HEPA filters are fully scannable. Because there are separate exhaust and supply blowers, the downflow is established, and then the inflow, by adjusting the respective blowers’ speeds. Like the Logic+ models, this is handled by a menu-driven display. If during certification, the customer wants the sash height changed from 8” to 10”, or vice versa, it can be done electronically, without having to relocate the sash height switches.

Find out more about the Purifier Axiom

* The request was for a Type B2 cabinet that could operate at a constant exhaust system vacuum of only 0.25 inches of H2O, a measure of effective efficiency that was impossible for any existing Type B2 BSC to produce in 2012.

| chevron_left | How to select the correct Cold Trap | Articles | Zero Net Energy (ZNE) lab uses filtered fume hoods | chevron_right |