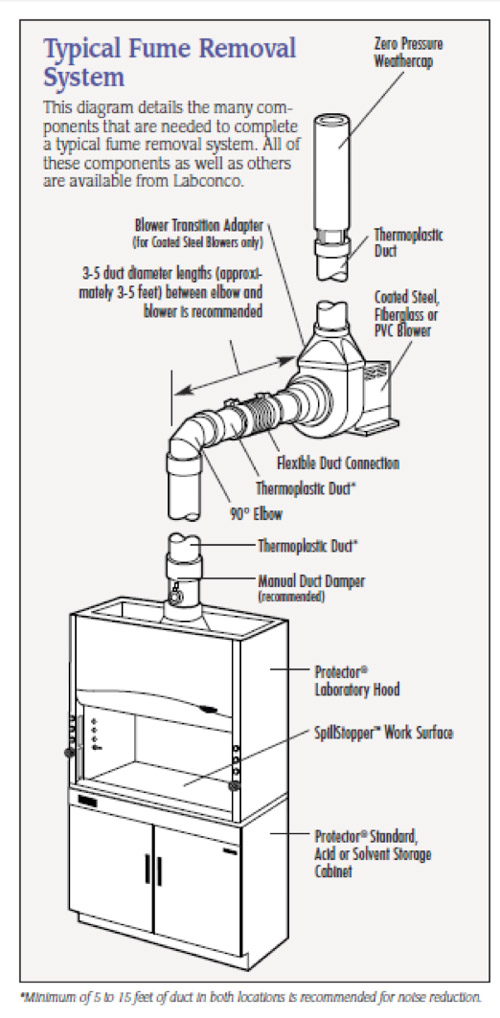

Zero Pressure Weathercap for vertical exhaust protection

Dealing with dangerous vapors that can corrode equipment is part of designing any exhaust mechanical system for a fume hood. The implementation of a straight, vertical exhaust is imperative to ensure that all harmful vapors are exhausted up and away from the surrounding environment, as well as to keep the mechanical system running at peak performance.

Dealing with dangerous vapors that can corrode equipment is part of designing any exhaust mechanical system for a fume hood. The implementation of a straight, vertical exhaust is imperative to ensure that all harmful vapors are exhausted up and away from the surrounding environment, as well as to keep the mechanical system running at peak performance.

Normal mechanical systems often terminate in cone-shaped caps, but those will not work to exhaust a fume hood mechanical system’s harmful, chemical-laden air. The contaminated air will continuously meet with resistance at the end cap, quickly resulting in corrosion of the ductwork and a tumult of eddying fumes. Sometimes the termination can even be turbulent enough to compromise the exhaust system. A Zero Pressure Weathercap can save the day; any fume hood mechanical system without one is incomplete.

What is a Zero Pressure Weathercap (Also called a No-Loss Stackhead)?

A Zero Pressure Weathercap is meant to attach as the exhaust termination of the fume hood mechanical system. The design of the component is essentially two cylinders, one inside of another. The smaller cylinder on the inside is not as tall as the outer cylinder. Depending on material and construction, sometimes there is a flange at the top to connect it to guy-wires.

How does it work?

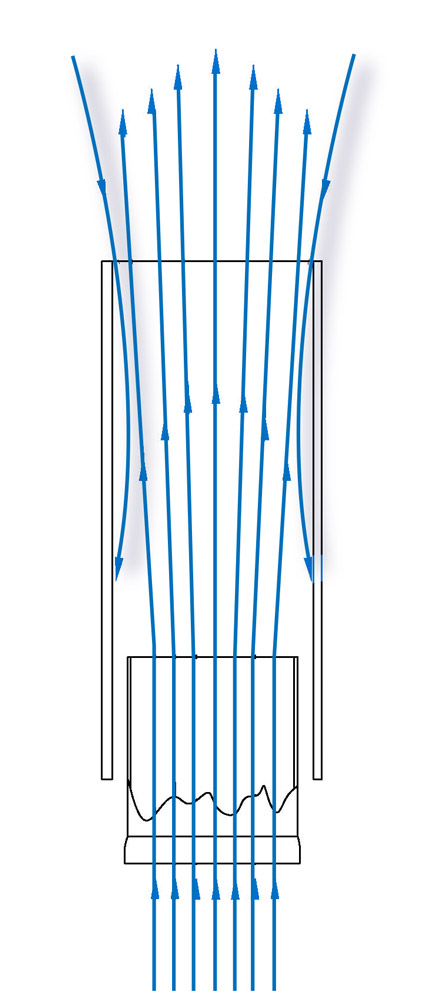

As air flows through a round duct, the velocity and pressure are near zero on the outside perimeter of the duct. The highest velocity is in the center, away from the outer walls. Therefore the rain follows the path of least resistance to the outside of the duct where there is near zero pressure and near zero velocity. The outside cylinder is slightly larger than the inside cylinder; therefore, rain has nowhere to pool. The two cylinders are welded together with spacers so the rain water has plenty of room to fall between the two cylinders and onto the roof. Even if the blower is not running, natural convection will bring air in from between the spacers and create this air movement.

What does it do for me?

What does it do for me?

It allows the bad air to exhaust with little turbulence, while not allowing rain to enter. This protects the blower and fume hood components from being damaged by rainwater.

Why do I need one?

A Zero Pressure Weathercap needs to be implemented in order to meet the ANSI Z9.5 standard for vertical exhaust, and to not allow rain to enter the fume hood system. It has no moving parts and requires no servicing or upgrading after it is installed, unless it starts to corrode. In the event it does need to be replaced, it is an inexpensive part of the duct system that can be easily accessed for installation.

This one simple piece of equipment can make a huge difference in the functionality of your fume hood mechanical system. It is an inexpensive solution to keep your fume hood dry while still maintaining an open space to vertically exhaust contaminated air.

| chevron_left | 5 common myths about lyophilization | Articles | Using a Controlled Atmosphere Glove Box with an exterior liquid nitrogen tank | chevron_right |