Summary of the Protector Filtered Glove Boxes Particulate Control Performance Tests

Labconco has finished the redesign of the Protector® Glove Boxes. The new Protector HEPA-Filtered and ULPA-Filtered Glove Boxes offer enhanced particulate containment and now provide the operators with real-time performance data on internal static pressure, air volume flow rates in cubic feet per minute and total air volume changes per minute.

These Glove Boxes feature a built-in blower with bag-in/bag-out HEPA or ULPA filters. The glove boxes can create an internal clean room environment and/or contain and remove hazardous particulates released within the main chamber environment.

Protector Filtered Glove Boxes provide the highest level of particulate control and containment when working with hazardous particulate chemicals. Common applications include the manipulation of nano-particulates and the weighing of hazardous powders with an analytical balance.

Particulate Control and Containment Test Procedure

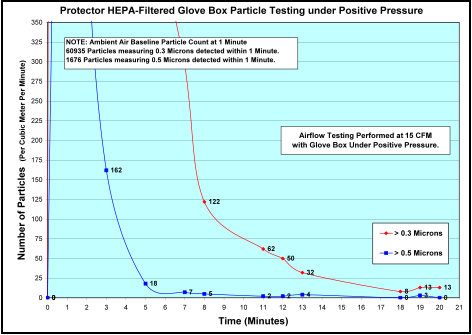

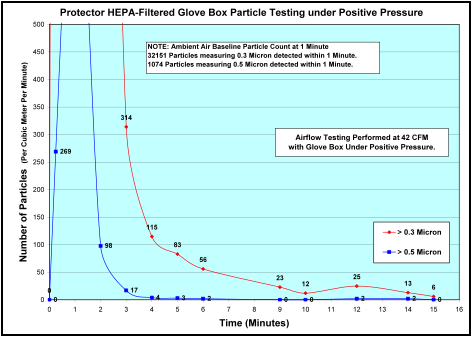

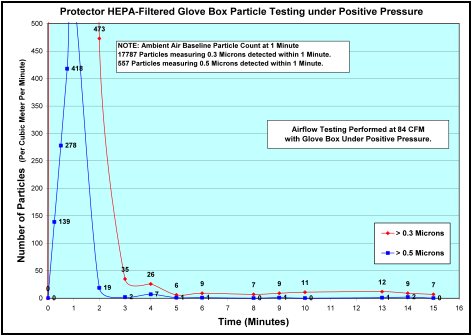

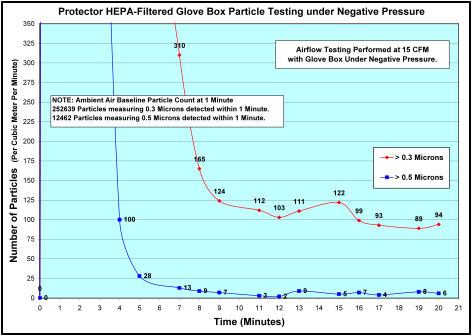

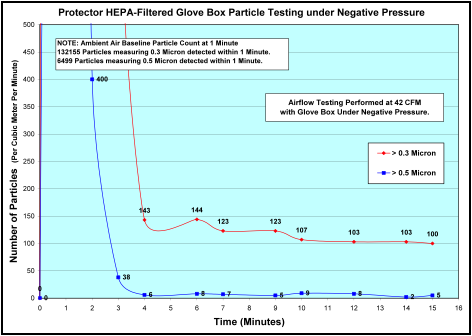

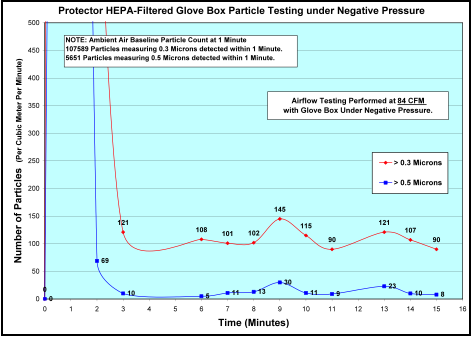

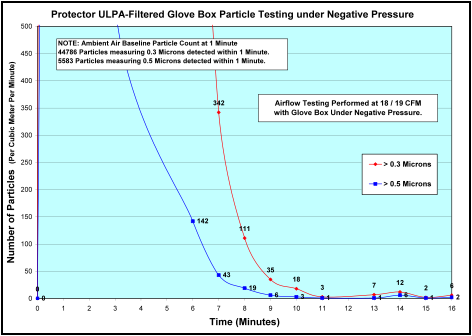

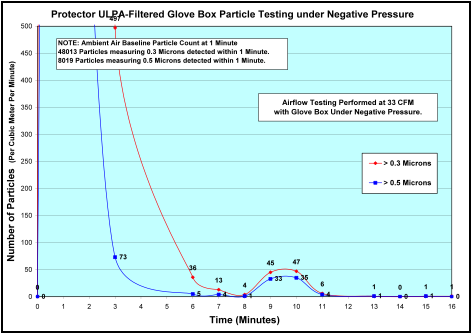

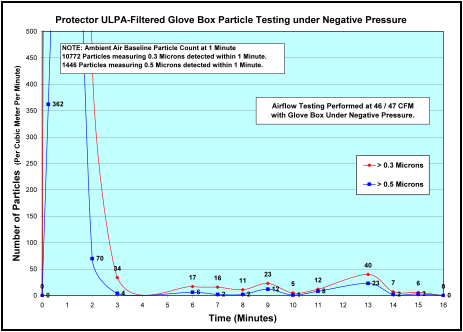

The purpose of the Airborne Particulate Tests is to define the particulate dilution rates and the achievable cleanliness levels within the glove box. The tests were conducted over the range of possible airflow volume settings provided by the glove box blower speed control, approximately 15 to 85-CFM.

Starting with a normal ambient laboratory air particulate condition, a CLiMET particulate counter was used to measure airborne particulate levels of 0.3 and 0.5 microns during a 15-20 minute time period within the glove box main chamber and provide quantitative particulate cleanliness levels. The procedure was performed twice for both possible positive and negative pressure operation functions.

Test Equipment Used

- Protector HEPA and ULPA Filtered Glove Box, Parts #5065010 and 5065510

- Innovation Particle Counter (Model CI-500 /manufactured by CLiMET Instruments)

Particulate Testing Results

Airborne particulate levels, measured under both negative and positive pressure conditions, within the main chamber of the Protector HEPA and ULPA Filtered Glove Box were reduced to below ISO Class 5 conditions (= Class 100) and achieved ISO Class 3 conditions (= Class 1) in less than 5 minutes at all operational airflow volumes. Results for the maximum airflow volumes are provided in the appendix.

Airborne Particulate Test— HEPA-Filtered Glove Box (Positive & Negative) Pressure

Airborne particulate levels measured under negative and positive pressure conditions within the main chamber of the Precise® HEPA Filtered Glove Box were reduced to below ISO Class 5 conditions (= Class 100) and achieved ISO Class 3 conditions (= Class 1) in less than 5 minutes at all operational airflow volumes. Results for the maximum airflow volumes are provided in the appendix.

Airborne Particulate Test - ULPA-Filtered Glove Box under Negative Pressure

Airborne particulate cleanliness (measured under negative pressure) within the main chamber of the glove box exceeded ISO Class 5 conditions (equivalent to Class 100) and exceeded ISO Class 3 conditions (equivalent to Class 1) at minimum blower speed, 50% and maximum operational airflow volumes. The maximum air flow test results are provided in the appendix.

Performance Validation

Airborne particulates measured under both positive and negative pressure operation conditions within the glove box main chamber exceeded ISO Class 5 conditions and achieved ISO Class 3 conditions. The testing validates the effectiveness of the inlet HEPA & ULPA Filter and the blower’s dilution rates. It also verifies levels of cleanliness obtainable within glove box chamber. ISO #3, particulate levels were achieved even at the lowest blower speed setting.

The Inlet and Exhaust HEPA & ULPA filters are identical in design and housing construction. The performance and cleanliness of the Exhaust HEPA & ULPA-filtered air volume will be identical to the inlet HEPA & ULPA filter.

Conclusion

The performance goal was met: the Protector HEPA and ULPA Filtered Glove Boxes remove airborne particulates (measured under positive and negative pressure) within the main chamber of the glove box. Particulates are reduced to below ISO Class 5 conditions (equivalent to Class100) and achieved ISO Class 3 conditions (equivalent to Class 1).

The Protector HEPA and ULPA Filtered Glove Boxes offer all the advantages of a low volume, HEPA filtered ventilation enclosure system, but provide a totally isolated working environment. Operators can utilize the blower control to achieve high rates of contaminant dilution within the totally enclosed main chamber which provides an absolute level of containment for chemical hazards that open sash fume hoods and balance enclosures cannot.

Protector HEPA & ULPA Filtered Glove Box Operational Guidelines

The test results indicated the Protector HEPA-Filtered Glove Box provided acceptable containment and performance under normal operating conditions. The following operational guidelines are provided to help ensure satisfactory performance of the Protector HEPA-Filtered Glove Box.

-

Allow the glove box to clean up the main chamber air volume by operating for 2 - 5 minutes at 50 - 100 % speed setting at start up before starting normal operating procedures.

-

The gloves will inflate and extend across the work surface when the glove box is operated under negative pressure. Ensure items in the glove box will not obstruct the movement of the gloves. This will help reduce the potential for spills and unnecessary contamination. Using glove port covers can eliminate glove inflation during dilution or venting operations.

-

Only load materials required for the procedure. Do not overload the glove box.

-

After loading required materials, allow the glove box to operate for 2 - 5 minutes to reduce or purge airborne contaminants from the work area before beginning procedures.

-

Always segregate all clean and contaminated materials inside the glove box and clean interior surfaces per user’s protocol for chemical contaminants in use.

-

When conducting normal operating procedures with the glove box in negative pressure mode, the blower speed control should be set to 50% or less.

-

All open trays, weigh vessels or containers should be sealed and surface decontaminated before being removed from the glove box. Alternatively, contaminated objects can be sealed in clean transfer bags (wipe down the transfer bag exterior) before being removed from the glove box.

-

When operating the glove box in positive pressure mode, start the blower at 50% speed or greater for 5 - 10 minutes before lowering the blower speed to begin work. This protocol is required to purge and dilute airborne contaminants from the work area.

- Upon completion of work, the glove box should be allowed to operate (with the interior transfer chamber door open and the exterior transfer chamber door closed) for 5 minutes undisturbed at 100% speed or for 10 minutes undisturbed at 50% speed. This safety protocol is required to purge airborne contaminants before closing the interior transfer chamber door, and removing sealed material through the exterior transfer chamber door.

This report provides a description of test methods, a summary of test results, and recommendations to help ensure proper performance. Please note that data provided herein are indicative of the performance of the Protector HEPA-Filtered Glove Box under the prevailing operating conditions at the time and date of the tests.

Any questions concerning information or conclusions contained within this report should be referred to Labconco Corporation.

APPENDIX

Airborne Particulate Test (Positive Pressure)

Airborne Particulate Test (Negative Pressure)

Airborne Particulate Test with ULPA Filter (Negative Pressure) (230V)

| chevron_left | XPert Nano Enclosures Particulate Containment Test Results | Articles | View the October Logic ad | chevron_right |