Does that lab really need an explosion-proof fume hood?

We receive many requests from customers for explosion-proof (EP) fume hoods. Customers often think that if they are working with a flammable chemical they automatically need an EP hood. In reality, only a small percentage of customers really need EP fume hoods.

Determining whether you need an explosion-proof (EP) fume hood may seem like a daunting task. Really, there are just a few things to consider in determining if an EP hood is needed for your application.

A common misunderstanding of EP hoods is that they are designed to contain an explosion. Actually, most manufacturers would define an EP hood as one that is modified to eliminate spark potential outside the fume hood, and consequently reduce the chances of igniting a flammable atmosphere. EP hoods are not designed to contain explosions.

The National Electrical Code (NEC), or National Fire Protection Association (NFPA) 70, classifies rooms with potentially explosive or flammable atmospheres as either Class I, II, or III and Division 1 or 2 within these Class options. Class I locations are where flammable gasses or vapors may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. Class II and III locations are rooms with the presence of combustible dust and fibers, respectively, and are not typical of the atmosphere in a laboratory environment.

If a fume hood is located in a space with any of these electrical classifications, the hood should be EP rated, regardless of the kind of work going on inside the hood. This is because labs with a potentially flammable atmosphere must be void of spark potential; this includes the electrical components outside of the fume hood’s airstream.

An EP laboratory hood is equipped with specially designed electrical components, such as EP rated switches, receptacles and internal wiring. The fume hood manufacturer does not supply these EP components; rather they are supplied and installed on site by a licensed electrician in order to meet all state and local codes. For this reason, all EP modified Labconco fume hoods come with an EP rated incandescent light fixture, and without bulbs, wiring, switches, or duplexes.

NFPA 70 also notes that exhausted enclosures with ventilation needed to maintain vapor concentrations below 25% of the Lower Flammability Limit (LFL) or Lower Explosion Limit (LEL), should be rated Class I/Division 2. However, NFPA 45, Fire Protection for Laboratories Using Chemicals, 5.5.2, notes that “…chemical fume hood interiors shall be considered as unclassified electrically with respect to Article 500 of NFPA 70…” unless an unusual hazard is identified.

So, simply working with a flammable chemical is not justification for the use of an EP fume hood. The interior of standard chemical fume hoods are void of electrical components; the lighting is isolated from the interior via a piece of thick safety glass, the electrical duplexes and switches are positioned on the exterior, all the wiring is contained within the sidewall of the hood, and even the thermister or hot wire from the airflow monitor is in an isolated airstream. From the factory, there is no spark potential on the inside of a standard chemical fume hood. Combine this with a continuous stream of clean room air, and there is very little chance of flammable combustion inside a chemical fume hood.

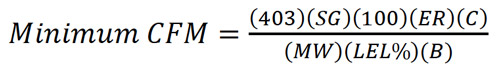

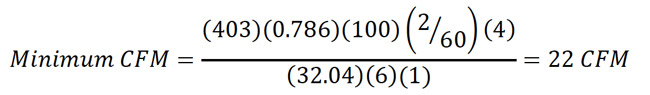

However, when working with flammable chemicals, it is not uncommon to validate that a hazardous concentration will not exceed 25% of the LEL or LFL. This is determined by calculating the “dilution factor” and comparing it to the volumetric rate of air flowing through a fume hood. For example, assume we are evaporating 2 pints per hour of Methanol at 70 degrees F. From Industrial Ventilation, A Manual of Recommended Practice, 2.5:

Where SG is specific gravity, ER is evaporation rate in pints per minute, C is a safety factor between 4 and 12 (4 is used for 25% of LEL), MW is molecular weight, LEL is the Lower Explosive Limit as a percent, and B is a temperature constant (Use 1 for temperature up to 250 degrees F, and use 0.7 for temperature above 250 degrees F). For Methanol, LEL is 6%, SG is 0.786, MW is 32.04, and from above we know that ER is 2/60, C is 4, and B is 1.

If you find that the minimum CFM required to sustain a concentration below 25% of the LEL surpasses your fume hood’s volumetric rate of air, or if there is a concern that your air handling equipment could fail, thus increasing the concentration of your flammable chemical above this threshold, you may want to consider an EP fume hood as well as a Class I room electrical classification, as this would be grounds for an unusual hazard.

Most Labconco fume hoods are candidates for an EP modification. Visit www.labconco.com for more information on our fume hoods; and please contact your Labconco Sales Representative, or call 800-821-5525, for ordering information and help determining if an EP hood is right for your application.

| chevron_left | Labconco at Pittcon 2013 revisited | Articles | Inclination™ Technology: features that reinforce what humans are inclined to do | chevron_right |