3 Explosion-Proof Fume Hood Myths

Labconco receives many inquiries about applications that may require explosion proof fume hoods (EP hoods). There are several common misconceptions about EP hoods, and in reality, only a small percentage of situations actually require one. This article will tackle three common EP fume hood myths and discusses what makes a hood explosion proof, when one is needed, and what the modification means for user protection.

Myth #1: “Explosion-proof hoods are shipped with documented EP certification”

A hood is made explosion proof by removing the potential for creating a spark. This means the hood is delivered without any wiring or switches, and the standard light fixture is replaced with an explosion-proof incandescent light fixture (Labconco does not provide the incandescent light bulb).

All wiring must be done in the field per local code. So if the local fire codes require an explosion-proof hood, or if the room itself is rated* such that the atmosphere of the room has a high concentration of flammable vapors or particulates, then the hood will need to be explosion proof. If you’re placing a hood in an existing room, an easy way to tell if an EP hood makes sense is to look around to see if there are any standard electrical outlets or light switches in the room. If it has standard electrical components, an EP hood has no business being placed there. Putting an EP hood next to a standard electrical component that can produce a spark voids any rating that hood would carry. So if you have an EP hood, that means it cannot have an airflow monitor that plugs in, nor any electrical outlets on the fume hood corner posts – that means say goodbye to the hotplate you were planning on using, unless both the hotplate, and the electrical outlet you are plugging it into are both explosion proof.

Installation costs are going to be higher for an EP hood too, since the hood will have to be wired by a licensed electrician. There will likely be metal conduit for the wiring connected to the light fixture. You’ll need to purchase a standard switch to be mounted on a wall outside of the room in a non-rated area, or purchase an EP switch, mount that to a wall inside the rated room, and have the electrician wire the hood to that switch. Explosion proof electrical outlets are too large to be mounted on the corner posts, so those will have to be mounted on a wall in the room. While adding difficulty to the installation, these things add incremental costs as well.

These are only modifications to a standard fume hood. So when an EP fume hood is shipped, it does not include documentation or a listing that certifies the hood as explosion proof since any certification would be fully contingent upon its installation.

Myth #2: “I’m working with flammable chemicals, so I need an explosion-proof hood”

Since all of these modifications occur on the exterior of the fume hood, this modification has to do with conditions in the room where the fume hood will be installed, and not with the chemical application. People often think they need an EP hood when they are working with flammable chemicals. Talk to any salon professional that has used hairspray or acetone nail polish remover and I’m sure they’ll tell you they do not have to have an EP fume hood to use those items, and probably even use them near standard electrical outlets. In a typical fume hood system, there is nothing electrical in the air stream.

All electrical components that could be mounted on a fume hood (i.e. blower, light switches, electrical outlets and airflow monitors) are all mounted on the corner posts, out of the way of the flammable vapors. Additionally, the air exhausting through the fume hood continually dilutes the air inside the fume hood, making it hard to reach most chemicals’ lower explosive or flammability limits. NFPA 70 notes that exhausted enclosures with ventilation needed to maintain vapor concentrations below 25% of the Lower Flammability Limit (LFL) or Lower Explosion Limit (LEL), should be rated Class I, Division 2. However, NFPA 45, Fire Protection for Laboratories Using Chemicals, notes that the interiors of laboratory chemical fume hoods are exempt from electrical classification if there is not an unusual hazard identified where vapors come within 25% of the LEL.

When working with flammable chemicals, it is not uncommon to validate that a hazardous concentration will not exceed 25% of the LEL or LFL. This is determined by calculating the “dilution factor” and comparing it to the volumetric rate of air flowing through a fume hood. For example, assume we are evaporating 2 pints per hour of methanol at 70 degrees F.

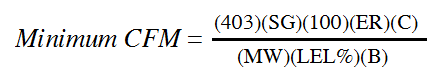

From Industrial Ventilation, A Manual of Recommended Practice, Dilution Ventilation for Fire and Explosion:

Where SG is specific gravity, ER is evaporation rate in pints per minute, C is a safety factor between 4 and 12 (4 is used for 25% of LEL), MW is molecular weight, LEL is the Lower Explosive Limit as a percent, and B is a temperature constant (Use 1 for temperature up to 250 degrees F, and use 0.7 for temperature above 250 degrees F).

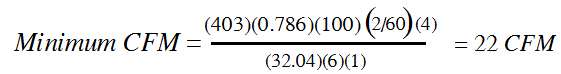

For methanol, the LEL is 6%, SG is 0.786, MW is 32.04, and from above we know that ER is 2/60 since we are evaporating 2 pints per hour, C is 4, and B is 1.

In this scenario, the exhausted volume through the fume hood will exceed 22 CFM, therefore this scenario does not present an unusual hazard. If you find that the minimum CFM required to sustain a concentration below 25% of the LEL surpasses your fume hood’s volumetric rate of air, or if there is a concern that your air handling equipment could fail, thus increasing the concentration of your flammable chemical above this threshold, you may want to consider an EP fume hood as well as a Class I room electrical classification as this would constitute an unusual hazard.

Myth #3: “Explosion proof hoods are designed to protect the user in the event of an explosion”

A common misunderstanding of EP hoods is that they are designed to contain an explosion. EP hoods are not designed to contain explosions. Fume hoods are built with a safety glass sash that provides a physical barrier, however, it is still glass and therefore, in the event of a blast, it can break. The user would be directly exposed to the explosive force through both the sash and the sash opening in the event of an explosion inside the hood. EP hoods are meant to prevent explosions, not contain them.

In conclusion, simply working with a flammable chemical is not justification for the use of an EP fume hood. The interior of chemical fume hoods are void of electrical components; the lighting is isolated from the interior via a piece of thick safety glass, the electrical duplexes and switches are positioned on the exterior, all the wiring is contained within the sidewall of the hood, and even the thermistor or hot wire from the airflow monitor is in an isolated airstream. From the factory, there is no spark potential on the inside of a standard chemical fume hood. Combine this with a continuous stream of clean room air, and there is very little chance of flammable combustion inside a properly functioning standard chemical fume hood.

Most Labconco fume hoods are candidates for EP modification. Contact your Labconco representative for more information if you think an explosion-proof hood might be right for your application.

* The NEC and NFPA 70 classify rooms with potentially explosive or flammable atmospheres as either Class I/II/III and Division 1/2. Class I locations are where flammable gasses or vapors may be present in the air in quantities sufficient to produce explosive or ignitable mixtures. Class II and III locations are rooms with the presence of combustible dust and fibers, respectively, and are not typical of the atmosphere in a laboratory environment.

| chevron_left | How to handle and preserve wet DNA evidence | Articles | 3 ways to get the most out of a high performance lab ventilation system | chevron_right |